PC Engineering Plastic with Halogen Free Flame Retardant for LCD Back Light Unit Parts

PC Engineering Plastic with Halogen Free Flame Retardant for LCD Back Light Unit parts GF Reinforced PC compound materia

Basic Info

| ODM/OEM | Accept |

| Sample | Avaiable |

| Grade | Injection |

| Glass Fiber | 5%-60% |

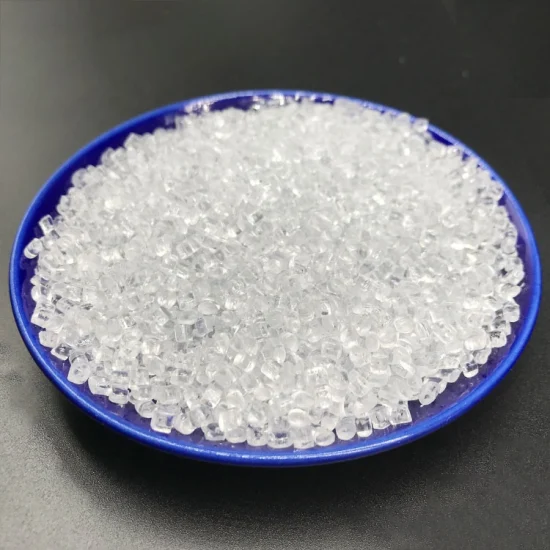

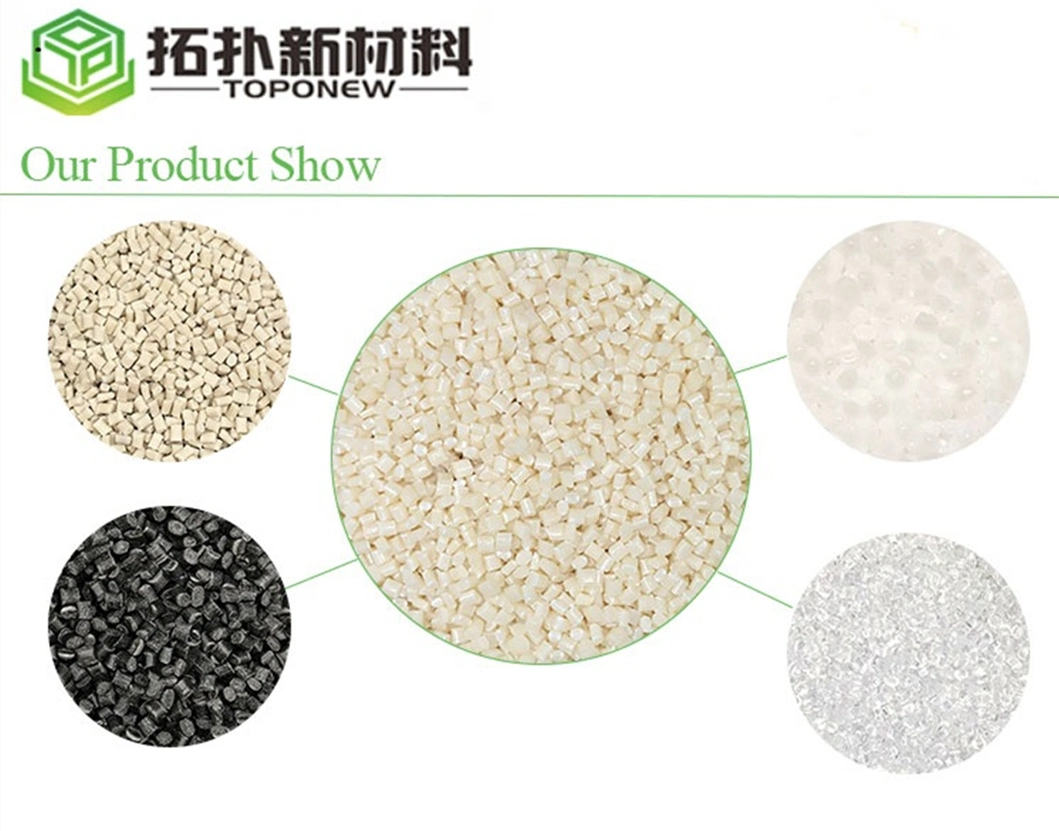

| Shape | Pellets, Granules, Particle |

| Transport Package | 25kgs/Bag |

| Specification | 65*40*15cm |

| Trademark | TOPO NEW |

| Origin | China |

| HS Code | 390740000 |

| Production Capacity | 100kgs/Week |

Product Description

PC Engineering Plastic with Halogen Free Flame Retardant for LCD Back Light Unit parts

GF Reinforced PC compound material is usually filled with 5%-30% glass fiber as reinforcing agent.After combination, the compound material has excellent toughness, strength, stress crack resistance, high hardness and heat resistance. It is also dimensionally stable and is able for spray. Materials can meet ROHS environmental requirements, and they are widely used in electronic components, bearing cages, gears, parts and components, automotive parts and so on. TOPO NEW MATERIAL can provide reliable customized services according to clients' specific requirements.PC(C010208 NA)| Product Description | Applications | ||||||||

| · Good dimensional stability | · Injection molding | ||||||||

| · Excellent heat stability | · Good mechanical properties balance | ||||||||

| Properties | Test Method | Test Condition | Unit | Typical Values | |||||

| Physical properties | |||||||||

| Specific Gravity | ISO 1183 | 23ºC | g/cm3 | 1.2 | |||||

| MI | ISO 1183 | g/10min | 9 | ||||||

| Ash | ISO 3451 | 800ºC,30min | % | 0 | |||||

| Mechanical properties | |||||||||

| Tensile Strength | ISO 527 | 50mm/min | MPa | 70 | |||||

| (yield) elongation | ISO 527 | 50mm/min | % | 123 | |||||

| Flexural Modulus | ISO 178 | 2mm/min | MPa | 2280 | |||||

| Cantilever beam notched impact strength | ISO180 | 23ºC | KJ/m2 | 66 | |||||

| Non-notched impact strength of cantilever beam | ISO179 | 23ºC | KJ/m2 | 72 | |||||

| Thermal properties | |||||||||

| Heat deflection temperature | ISO 75 | 1.80MPa | °C | 126 | |||||

| Melting Point | DSC | - | C | ||||||

| Other properties | |||||||||

| Flammability | UL94 | 1.5mm | V0 | ||||||

| Note: The data above is a typical value for reference, not guaranteed value. The data will vary with tool design such as gate type, gate location, gate number, injection molding process, and part thickness. The data will vary with different colors as well. Prior to using the material, please consult with TOPO NEW Material | |||||||||

| Processing Conditions | Range | ||||||||

| Melt Temperature | 304-327ºC | ||||||||

| Mold Temperature | 82.2-121ºC | ||||||||

| Pre-Dry needed | 121ºC, 4-8h | ||||||||

| Note: The above process condition is only for reference. The actual process should be adjusted according to different type of machine, mold design and product design. | |||||||||

Are you trading company or manufacturer?

We are manufacturer.

About Sample?

A 5 KG Free Sample can be offered per your request.

About Material Color?

We can make the material to your appointed color according to Pantone/RAL#.

How does your factory control the quality?Quality is the Priority, we always pay great importance to quality from beginning to end, and we have professional QC for item quality from spare parts to finished goods.

How many days for mass production?

20 days after all artwork and 30% deposit are confirmed.

How can I get the samples? is the sample free?

7-10 days to send free samples by DHL, TNT, UPS

Send to us