Polyamide (nylon 66) PA66 Material Virgin PA Plastic Granule PA6 PA66 PA6.6 GF35 GF30

1.Product Description Polyamide(PA) are also commonly known as Nylon, the most common types of polyamides are PA6 and PA

Basic Info

| Model NO. | PA6 |

| Plastic Forming Method | Injection |

| Color | White |

| Sample | Free |

| Delivery Time | 7-15days |

| Quantity | 25kg/Bag |

| Type | Virgin |

| Transport Package | Water-Proof Paper Plastic Bag |

| Specification | 25kg/bag |

| Trademark | SHIBO |

| Origin | China |

| HS Code | 3908909000 |

| Production Capacity | 20000tons/Year |

Product Description

1.Product DescriptionPolyamide(PA) are also commonly known as Nylon, the most common types of polyamides are PA6 and PA66, which are characterized by balanced mechanical, electrical and tribological properties. Nylons are often material of choice when it comes to applications that require high strength, rigidity and flame retardant ability.

Properties:

High strength,

High rigidity,

Good heat resistance,

Low water absorption,

Low shrinkage,

Self-lubricating properties, andGood processing properties2.The technical parameters

| PA6 chips | ||

| Brand/Grade | Relative viscosity | Features & Usage |

| YH800 | 2.85±0.03 | Medium viscosity, suitable for injection molding, flame retardant modification and spinning brown silk, monofilament, etc. |

| YH700 | 2.75±0.03 | Medium viscosity, suitable for injection molding, flame retardant modification and spinning brown silk, monofilament, etc. |

| LX275 | 2.75±0.03 | Medium viscosity, general purpose grade, bright chips |

| JQC-2750 | 2.75±0.03 | Used in fishing net, spinning, injection molding, packaging materials, etc., also used in modified plastic base material, after modified by glass fiber reinforced flame retardant, widely used in electrical appliances, machinery, electronics, automobile and other industries. |

| 1013B | 2.75±0.02 | Used in auto parts, power tools, sockets, building materials, hardware, fishing nets, spinning, plastic modification, packaging materials and other injection molding products. |

| M2500I | 2.5 | Medium viscosity , bright chips, direct injection, rapid prototyping, Good mold release performance |

| YH600 | 2.55 | Suitable for reinforcing modification, alloy and spinning brown silk, fishing net, etc. The characteristic molecular weight is moderate. |

| YH400 | 2.43 | Low viscosity, wear resistance, high flow, for electrical appliances and automotive applications |

| YH3400 | 3.40±0.03 | High viscosity, suitable for industrial silk, packaging film and high strength wear-resistant structural parts |

| BL1340H | 3.35±0.05 | High viscosity, home appliance automotive applications |

| BL2280H | 2.71 | Food grade high temperature resistant electronic and electrical parts, injection molding |

| BL2280Z | 2.70±0.03 | Uses: auto parts, electrical and electronic plug-ins, mechanical parts, baby carriage parts, wear-resistant pulleys, gears, ties and their complex shape products. Features: good fluidity, easy demoulding, short molding cycle, good dimensional stability, good mechanical properties, excellent comprehensive performance, can replace similar products: 1013B \ F223-D \B3S \ M2500I \ B30S |

| BL3240H | 2.48 | High flow, low viscosity, fiber grade, injection molding, spinning, application: fitness equipment, thin wall products, wire, home appliance parts, automotive applications, power tools, electrical and electronic parts, cable, general purpose. |

| Toughened / Reinforced / Flame-retardant PA6 | ||

| Grade | Filler | Features & Usage |

| WBG35H | 35% Glass fiber | high speed turntable 8000 RPM for garden machinery, agricultural applications, industrial machinery |

| WB3H-4 | / | For high torque screw, nut, shaft, shaft, gear and other super strength industrial parts, injection molding and extrusion |

| BAL30Z | / | Extrusion grade, used for all kinds of vehicle oil pipe, also can be used for injection molding for other need toughness, softness products |

| B25Z-20/40/60 | Impact modified | Impact modified nylon 6 can be used for cold-resistant products and industrial parts of -20, -40, -60ºC |

| BFRG33XH | 33% Glass fiber, Red phosphorus flame retardant | Used for environmental protection, halogen-free, high flame retardant, anti-warping, need high strength, anti-fatigue electronics, electrical appliances and other industrial components |

| BG15 | 15% Glass fiber | Easy injection molding, rapid prototyping; Used for electronic appliances and medium - rigid thin - wall industrial parts. Good surface finish. |

| BG33H | 33% Glass fiber | Easy injection molding, used for electronic and electrical skeleton and high rigidity and thermal stability of industrial parts, fan blades and electrical insulation parts, good surface finish. |

| BG50 | 50% Glass fiber | Used for high rigidity, low warping, high strength, heat resistant electronic and electrical industrial parts and fan blades, can replace long glass fiber reinforced nylon 6; The surface is smooth and clean. |

| BG10Z | 10% Glass fiber | used for industrial parts that require cold resistance, uv resistance, rigidity and toughness |

| BG2010 | 30% Glass fiber | Used for high strength, high rigidity, hardness, and dimensional stability of the components, window decoration special materials |

| BG30C8 | 30% Glass fiber | Hydrolysis resistance, cold resistance, used for water pumps, water meters, pipe joints, etc |

| BG30HUV1 | 30% Glass fiber | Heat resistance, weather resistance, uv resistance, used for car door handle, reflector base and other outdoor parts |

| BG30W | 30% Glass fiber | No drying, direct injection molding, stable size, rapid molding; Good surface finish; Used for high precision parts. |

| BG30Z-30 | 30% Glass fiber | Impact modified. Used for industrial parts requiring strength and toughness. Cold resistance -40 ºC |

| BG33HSL | 33% Glass fiber | Used for high rigidity, high strength, stable size, long-term heat resistant electronic and electrical industrial components; Uncolored HSL grade, without the addition of color, the final product after injection molding will be light green |

| BG33HFL | 33% Glass fiber | Ultra high liquidity; Used for ultra-thin parts and high-precision electrical industrial parts with complex shapes |

| BG35FWUV | 35% Glass fiber | Uv aging resistance, high strength, high rigidity, good uv linear resistance, used for outdoor industrial components. |

| BG40Z | 40% Glass fiber | used for rigid and impact-resistant parts of automobile and machinery industry. It can resist fatigue, weather and low temperature. Can replace DSM K224-PG8 |

| BG40H8 | 40% Glass fiber | Impact modified. Can replace reinforced PA66 |

| BG55L | 55% Glass fiber | With high strength and rigidity, can be used for complex parts, good surface finish |

| BG65L | 65% Glass fiber | With high strength and rigidity, can be used for complex parts, good surface finish |

| BG70H | 70% Glass fiber | For industrial parts requiring ultra-high rigidity, can replace metal materials |

| 5020T | / | Toughened, high toughness, high impact resistance, low temperature -40ºC, application: electronic appliances, industrial machinery, automobile parts, injection molding |

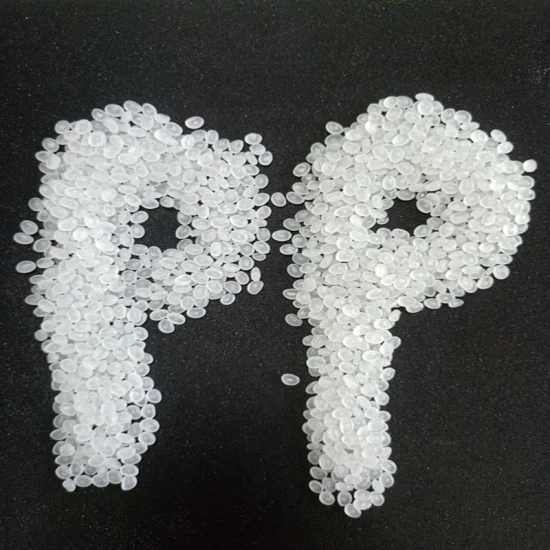

Inlet manifold of automobile engine, radiator tank parts, motor cover, tire cover, tension wheel, cooling fan, jetting machine accessories, electronics, connection terminal, disconnector, bearing cage, power tools cover, high performance gear, coil skeleton, textile accessories and so on.4.Company ProfileHandan Shibo New Material Co., LTD, starting from 2010, is constantly engaged in the production of plastic raw materials products,which is located in Handan City, Hebei Province, China, covering 500 acres, having more than 350 employees. The main products are carbon black ,masterbatch, modified(pvc, PP, pa6, pa66, pbt, abs),Filler masterbatch,fireretardant,antioxidant,flexibilizer,plasticizer, and other plastic raw material(ldpe hdpe lldpe pvc pva pbt eva abs eps gpps hips pc pet etc. With years of hard work and development, we have achieved a certain scale with technical service team for users with high quality and professional service.5.product diplay

6. The package & delivery

1.Packing:

Water-Proof Paper Plastic Bag20mt/20'FCL2.Storage:The resin should be stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not be piled up in the open air.3.Transportation:During transportation, the product should not be exposed to strong sunlight or rain and should not be transported together with sand, soil, scrap metal, coal or glass. Transportation together with toxic, corrosive and flammable substance is strictly prohibited.7.Our advantage

1.We are able to provide customized service based on your requirements.

2. Competitive prices - directly from factory to customer.

3.Advanced equipments for testing and manufacturing.

4.Professional and good after-sale service

5. Free sample for testing

Send to us