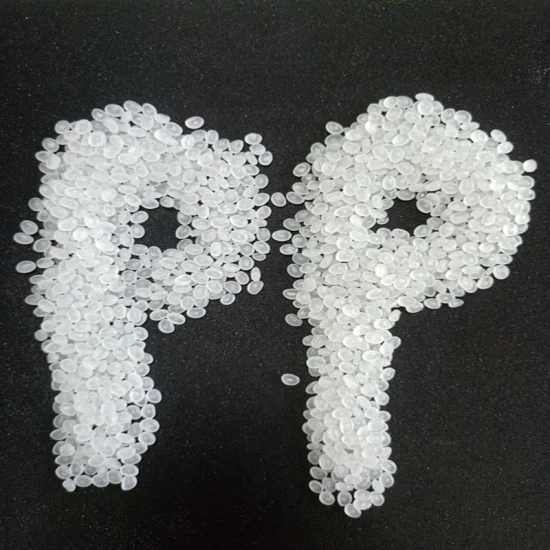

PP 1500 Meltblown Non Woven Virgin Plastic Granules PP

Basic Info

| Plastic Properties After Heated | Thermoplastic Plastics |

| Plastic Forming Method | Injection |

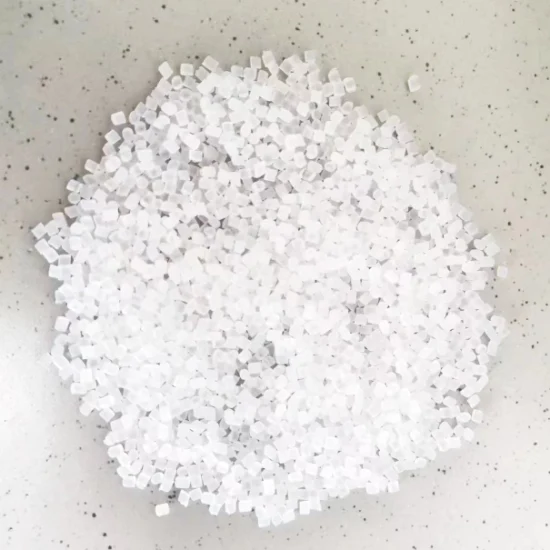

| Color | White |

| Carrier | PP |

| Bonding Function | High Temperature Resistant Adhesive |

| Morphology | Solvent |

| Classification | Hot Melt |

| Main Agent Composition | Inorganic Adhesive Material |

| Characteristic | Weatherability |

| Promoter Composition | Curing Agent |

| Composition | Organic Material |

| Transport Package | PP Bag |

| Specification | 25kg/bag |

| Trademark | AJ |

| Origin | China |

| HS Code | 3901901000 |

| Production Capacity | 500tons/Month |

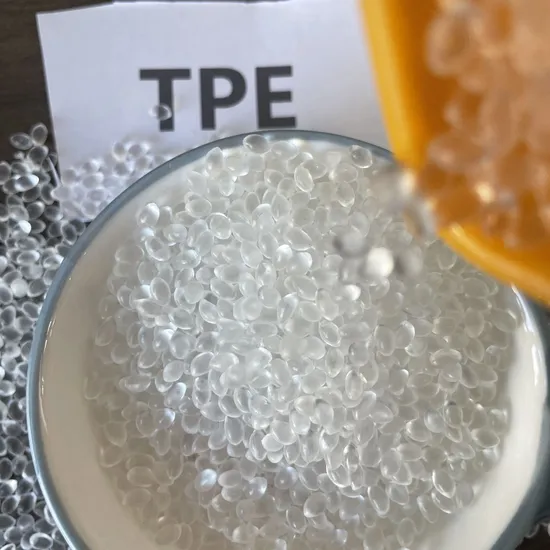

Product Description

Polypropylene, referred to as PP, is a colorless, odorless, non-toxic, translucent solid substance.Polypropylene is a kind of thermoplastic synthetic resin with excellent performance. It is a colorless translucent thermoplastic lightweight universal plastic. With chemical resistance, heat resistance, electrical insulation, high strength mechanical properties and good high wear-resisting processing properties, polypropylene has been widely developed and applied in many fields such as machinery, automobile, electronics and electrical appliances, construction, textile, packaging, agriculture, forestry, fishery and food industry since it came out.

Detailed PhotosApplicationAcid and alkali resistance, organic solvent resistance, excellent electrical insulation, low temperature, still can maintain a certain toughness. Surface hardness, tensile strength, rigidity and other mechanical strength are higher than LDPE, close to PP, tougher than PP, but the surface finish is not as good as PP.

Poor mechanical performance, poor air permeability, easy deformation, easy aging, easy to brittle, brittle than PP, easy to stress cracking, low surface hardness, easy to scratch. Difficult to print, printing, need to carry out surface discharge treatment, can not electroplate, surface dull.

Used for extruding packaging film, rope, woven bag, fishing net, water pipe; Injection molding low-grade daily necessities and shells, non-load-bearing components, plastic boxes, turnover boxes; Extrusion blow - molded containers, hollow products, bottles.

Product Parameters| Item | Unit | Test method |

| Density | 0.954g/cm3 | ASTM D1505 |

| Melt Index(190°C/2.16kg) | 0.9 g/10 min | ASTM D1238 |

| Falling Weight Impact Strength | 50g | ASTM D1709 |

| Elmendorf Tear Strength | 10kg/cm | ASTM D1922 |

| Film Impact Strength | 160kg.cm/mm | ASTM D3420 |

| Youngs Modulus | 600/750MPa | ASTM D882 |

| Tensile Strength(YIELD) | 70/60MPa | ASTM D882 |

| Tensile Strength(break) | 30/30MPa | ASTM D882 |

| Elongation(break) | 650/750MPa | ASTM D882 |

| Vicat Temperature | 129 °C | ASTM D1525 |

| Low temperature brittleness | -70°C | ASTM D746 |

| Melt Temperature | 180-220°C |

1. Are youtrading company or Manufacturer ? We are factory.2.About Sample We provide samples, but you need to pay the sample fee and freight.

3. About Material We can customize the material according to customers' requirement.4. About Quality All the products must be tested strictly according to the testing procedure before shipment.5. About Delivery Period Normally delivered in 21 working days after the confirmation of order& payment. And it varies according to the material and quantity.6. About Payment term It's flexible, T/T, L/C at sight,100% in advance,30% in advance, the balance by copy B/L