Marlex Brand Film Grade HDPE Hhmtr-144

Description: This high molecular weight, hexene copolymer is tailored for blown film applications that require:Toughness

Basic Info

| Model NO. | HHMTR-144 |

| Feature | Polymer |

| CAS No. | 9002-88-4 |

| Formula | (C2 H4)N |

| Material | High Density Polyethylene/HDPE |

| Usage | General Plastics |

| Plastic Properties After Heated | Thermosetting Plastic |

| Plastic Forming Method | Film Pressure |

| Color | White |

| Transport Package | Plastic Bag |

| Specification | 25kg bag |

| Trademark | Sabic |

| Origin | China |

| HS Code | 391230 |

| Production Capacity | 2 Million Tons/Year |

Product Description

Description:This high molecular weight, hexene copolymer is tailored for blown film applications that require:Toughness and durability; Good processability; Good blending characteristics with HDPE HMW resins.

Applications:

Typical applications for HHM TR-144 include:T-shirt bags; Multi-wall liners; Trash bags.

Packaging:

In 25kg bag, 26-28MT in one 40HQ.

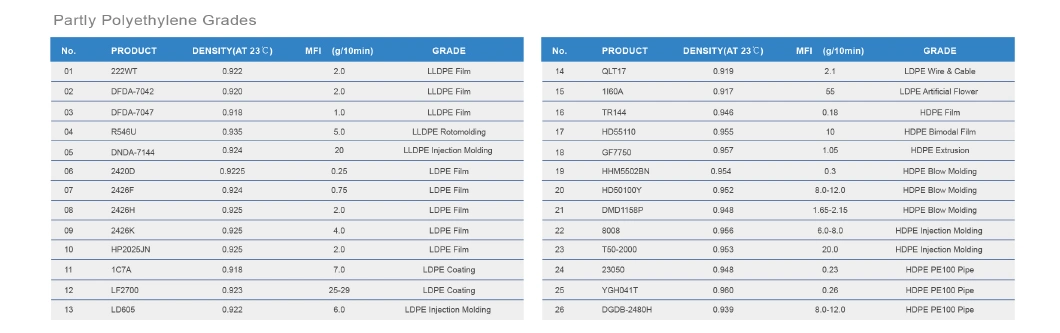

| No. | Properties | Value (SI Units) | Method |

| 01 | Density | 0.946 g/cm3 | ASTM D1505 |

| 02 | Melt Index, Condition 190°C / 2.16 kg | 0.18 g/10 min | ASTM D1238 |

| 03 | Brittleness Temperature, Type A clamp, Type I specimen | <-75°C | ASTM D746 |

| 04 | ESCR, Condition B (100% Igepal), F50 | >1000 hrs | ASTM D1693 |

| 05 | Flexural Modulus, Tangent - 16:1 span:depth, 12.7 mm/min | 1150 MPa | ASTM D790 |

| 06 | Dart Drop (66 cm) | 90 g | ASTM D1709 |

| 07 | Tensile Strength at Yield, 50.8 mm/min MD | 24 MPa | ASTM D882 |

| 08 | Tensile Strength at Yield, 50.8 mm/min TD | 26 MPa | ASTM D882 |

| 09 | Elongation at Break, 50.8 mm/min MD | 480% | ASTM D882 |

| 10 | Elongation at Break, 50.8 mm/min TD | 640% | ASTM D882 |

| 11 | Elmendorf Tear Strength, MD | 19 g | ASTM D1922 |

| 12 | Elmendorf Tear Strength, TD | 270 g | ASTM D1922 |

Send to us