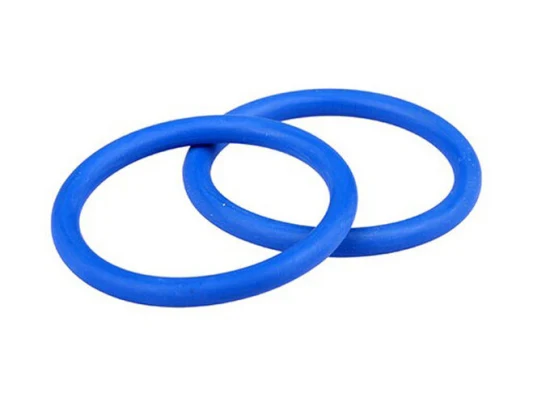

FKM Ffkm NBR EPDM HNBR Cr Kalrez Silicone PTFE O Ring O-Ring Rubber Seal Oring Hydraulic Cylinder Piston Rod Seal Ring

Overview Package size per unit product 30.00cm * 20.00cm * 2.00cm Gross weight per unit product 3.000kg Our Advantages1.

Basic Info

| Model NO. | lan100088-02 |

| Material | SIL |

| Application | Car |

| Type | Shaft Seal |

| Performance | High Pressure |

| Shape | O-Ring |

| Standard | Standard, Nonstandard |

| Customized Material | NBR, FKM, Silicone, EPDM, HNBR |

| Transport Package | PE Bag Inside, Carton Box Outside |

| Specification | Customized |

| Trademark | Lanhe |

| Origin | China |

| HS Code | 4016931000 |

| Production Capacity | 1000000 Piece/ Day |

Packaging & Delivery

Package size per unit product 30.00cm * 20.00cm * 2.00cm Gross weight per unit product 3.000kgProduct Description

Rubber O Rings Information | ||||

Material | Hardness (Shore A) | Temperature | Standard | Available |

NBR (Nitrile, Buna) | 60-90 | -40ºC - 110ºC | ID≤2000mmC/S≤40mm | AS-568 (America) |

FKM (FPM) | 70-90 | -20ºC - 220ºC | JIS-B2401 (Japan) | |

EPDM | 60-90 | -45ºC - 150ºC | DIN-3771 (Germany) | |

VMQ (Silicone) | 10-70 | -55ºC - 204ºC | BS-1806 (Britain) | |

HNBR | 60-90 | -48ºC - 180ºC | ISO3601 (International) | |

FFKM/Kalrez | 70-90 | -18ºC - 326ºC | ||

Resistance | Color | Certificate | Application | |

Engine Oil | Black | IATF16949 | Automotive Industry | |

Hydraulic Fluid | Brown | ISO14001 | Construction Machinery | |

Chemical | Green | ISO9001 | Machine Tool Equipment | |

Ozone | Red | REACH | Water Treatment | |

Steam & Hot Water | White | SGS | Chemical Processing | |

Low Temperature | Blue | RoHS | Hydraulic Pneumatic | |

High Temperature | Customize | Food grade Wras/LFGB | Industrial Manufacturing | |

2.The nitrogen freezing burr processor we used which is adopting advanced technology in china. The equipment is easy to operate with high efficiency and precision which remove the raw edges without damaging products.

3.The advanced full-size automatic measuring machine was introduced from Israel can make automatic quality inspection and sorting .The detection accuracy reaches 10μm and the speed reaches 300 pieces/min.

4.We have a professional customer service team with a complete service system and strong technical supports.5. Fast production & in-time delivery that never delay your project and usage.

6. One-stop custom service and value-added service to save your time and cost.

7. OEM/ODM Services are available. We can design and produce various Non-standard.Rubber Parts according to your PDF,3D or STEP drawing files.Certifications

FAQ

Q1:Are you a manufacturer or trading company?

A1: We are a factory with more than 20 years' experience.Q2: Can you do OEM parts?

A2.:Yes, we mainly do customized rubber and plastic parts. OEM service is available.

Q3:Do you provide samples?

A3:Yes, we could provide samples for you.

Q4:What about the lead time?

A4:It takes 15-20 days for making mould.It takes about 3 days to prepare samples.It takes about 3-6 days for shipping samples by FEDEX, UPS, DHL,TNT.The production lead time for mass order is as per the quantity.

Q5:How do you control the quality?

A5:All raw material we use are brand and new, material properties is stable. Skilled workers take care every details in producing and packing process.Quality control department inspect the product quality in each process.

Q6: What materials are available to produce from your side?A6: NBR, EPDM, SILICONE, HNBR,FKM, FLS, etc. tc oi

Q7:What is your terms of payment?

A7: Pay deposit by TT in advance balance, pay the balance payment before shipping.

Send to us