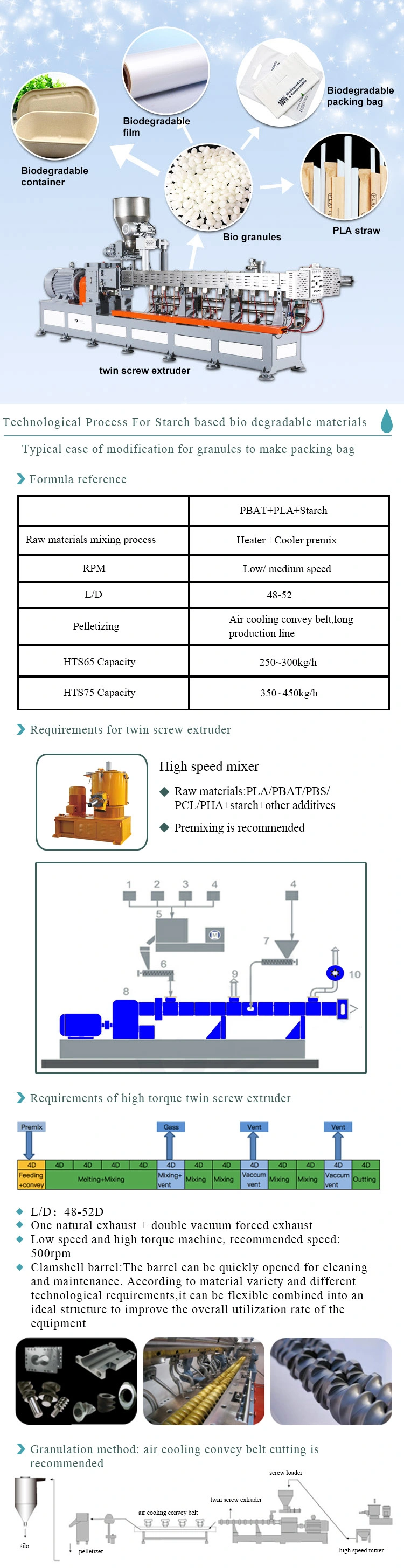

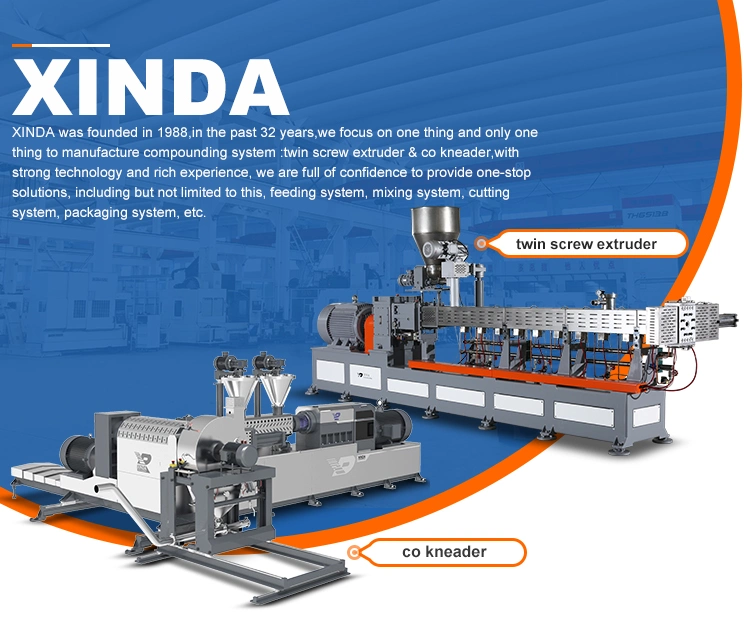

PLA Pbat Starch Biodegradable Plastic Granules Twin Screw Extrusion Machine

Basic Info

| Model NO. | PSHJ-65 |

| Warranty | 1 Year |

| Raw Material | Mixing |

| Screw | Double-Screw |

| Inverter | Inverter |

| Electromagnetic Heater | Electromagnetic Heater |

| Automation | Automatic |

| Computerized | Computerized |

| Customized | Customized |

| Certification | CE, ISO9001:2008, QS |

| Condition | New |

| Capacity | 500-600kg/H |

| Applications | All Kinds of Polymer Mixing |

| Electric Brands | Siemens / Schneider |

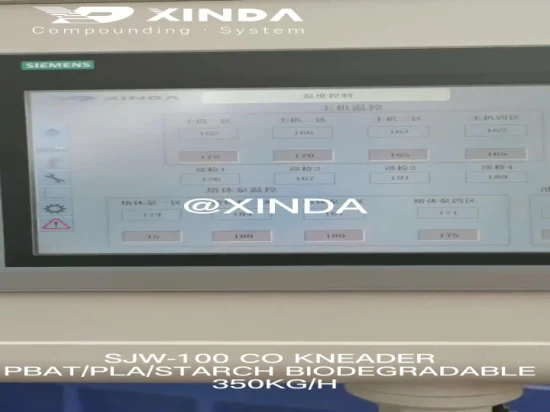

| Control | PLC + Touch Screen |

| Extruder Weight | 8000kg |

| Transport Package | Pallet and Wooden Box |

| Trademark | XINDA |

| Origin | China |

| HS Code | 84772010 |

| Production Capacity | 200sets/Year |

Packaging & Delivery

Package size per unit product 1000.00cm * 1000.00cm * 1000.00cm Gross weight per unit product 1000.000kgProduct Description

| Model | PSHJ-20 | PSHJ-35 | PSHJ-50 | PSHJ-65 | PSHJ-75 | PSHJ-127 |

| Screw Diameter:MM | 21.7 | 35.6 | 50.5 | 62.4 | 71 | 126 |

| Central Distance | 18 | 30 | 42 | 52 | 60 | 102 |

| Length Diameter Ratio | 28-52 | 28-52 | 28-52 | 28-52 | 28-52 | 28-52 |

| Main Motor Power | 4-5.5 | 22-45 | 75-110 | 110-185 | 160-280 | 90-160 |

| Max.Screw Speed:RPM | 600 | 600 | 600 | 600 | 600 | 600 |

| Output Torque per Shaft:N.m | 32-43 | 175-358 | 597-875 | 875-1472 | 1273-2228 | 850-1528 |

| Reference Output: KG/HOUR | 44336 | 20-80 | 80-200 | 150-350 | 300-600 | 800-1500 |

Application:

Various plastic inorganic filler, polymer blending (plastic alloy), plastic coloring, ect

Various engineering plastic reinforcement of glass fiber, flame-retartant pellets

Various antibacterial, insulated, toughening materials for specific uses

Light/biology degradable film materials, amylum degradable plastics and multi-functional anti-fog film materials, etc.

Specific material for automobiles and household appliance and cable materials, etc

Themoplastic elastomers, such as TPR, TPE, and SBS, etc

Regenerate pellets for PVC airproof pieces, thermo-soluble glue, etc

Application:

Various plastic inorganic filler, polymer blending (plastic alloy), plastic coloring, ect

Various engineering plastic reinforcement of glass fiber, flame-retartant pellets

Various antibacterial, insulated, toughening materials for specific uses

Light/biology degradable film materials, amylum degradable plastics and multi-functional anti-fog film materials, etc.

Specific material for automobiles and household appliance and cable materials, etc

Themoplastic elastomers, such as TPR, TPE, and SBS, etc

Regenerate pellets for PVC airproof pieces, thermo-soluble glue, etc