HDPE PE100 Virgin HDPE Granules HDPE Ygh-041t Black Pipe Grade

Product Description HDPE High density Polyethylene (HDPE): is a highly crystalline non-polar thermoplastic resin produce

Basic Info

| Model NO. | HDPE |

| Plastic Forming Method | Injection |

| Color | Black |

| Application | Injection Molding Products |

| Shape | Granuels |

| Melt Flow Rate | 0.8-1.2 G/10min |

| Feature | High Temperature Resistant |

| Transport Package | Woven Bag |

| Specification | 25kg Bag |

| Trademark | JLX |

| Origin | Hebei Province, China |

| HS Code | 3902100090 |

| Production Capacity | 10000ton/Year |

Product Description

HDPE

High density Polyethylene (HDPE): is a highly crystalline non-polar thermoplastic resin produced through the copolymerization of ethylene and a small amount of α-olefin monomer. HDPE is synthesized under low pressure and is therefore also called low-pressure polyethylene. HDPE is mainly a linear molecular structure and has little branching. It has a high degree of crystallization and high density. It can withstand high temperatures and has good rigidity and mechanical strength and anti-chemical corrosion.

Properties:High density polyethylene for non-toxic, tasteless, no smelly white particles, melting point is about 130 ° C, relative density of0.941 ~ 0.960. It has good heat resistance and cold resistance, chemical stability, but also has high rigidity and toughness, goodmechanical strength. Dielectric properties, environmental stress cracking resistance sex also is good.

Film Grade

| Item | Test condition | Test Method | Value | Unit |

| Density | ISO 1183 | 0.944-0.955 | g/cm3 | |

| MFR | 190°C/2.16kg | ISO 1133 | 0.03-0.07 | g/10min |

| Tensile strength at yield | ISO 527-2 | 22 | MPa | |

| Elongation at break | ISO 527-2 | >350 | % | |

| ESCR | F50,50°C,100% | ASTM D-1693A | 1000 | h |

| VICAT | ASTM D-1525 | 126 | °C |

Blown Grade

| Item | Test Condition | Test Method | Value | Unit |

| Density | ISO 1183 | 0.950~0.955 | g/cm | |

| MFR | 190°C/2.16kg | ISO 1133 | 1.7~2.5 | g/10min |

| Tensile strength at yield | ISO 527-2 | 24 | MPa | |

| Elongation at break | ISO 527-2 | >600 | % |

Injection grade

| Item | Test Condition | Test Method | Value | Unit |

| MFR | 190°C/2.16kg | ASTM D-1238 | 20 | g/10min |

| Density | --- | ASTM D-792 | 0.954 | g/cm3 |

| Tensile strength at yiled | --- | ASTM D-638 | 28 | MPa |

| Elongation at break | --- | ASTM D-638 | 250 | % |

| Impact tensile strength | --- | ASTM D-1822 | 42 | kJ/m2 |

| ESCR | ASTM D-1693 | 3 | --- | |

| VACIT | --- | ASTM D-1525 | 127 | °C |

1.Film grade is widely used in the production of packing bag, film and so on.2.Blow molding grade for making various bottles, cans, tanks , barrels Injection-molding grade is for making food cases, plastictrays, goods containers.3.Blow film product:Foodstuff packing bag,groceries shopping bags, chemical fertilizerlined with film, etc4.Extruded product: Pipe,tube mainly used in gas transportation, public water and chemicalstransport, such as building materials, gas pipe, hot water drain pipe etc: sheet material ismainly used in the seat, suitcase, handling containers.

1.Packing:25kg/ carton or 25kg/bag, or per your requirement.18mt/20'FCL

2.Storage:The resin should be stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not be piled up in the open air.3.Transportation:During transportation, the product should not be exposed to strong sunlight or rain and should not be transported together with sand, soil, scrap metal, coal or glass. Transportation together with toxic, corrosive and flammable substance is strictly prohibited.

Recycled HDPE granules

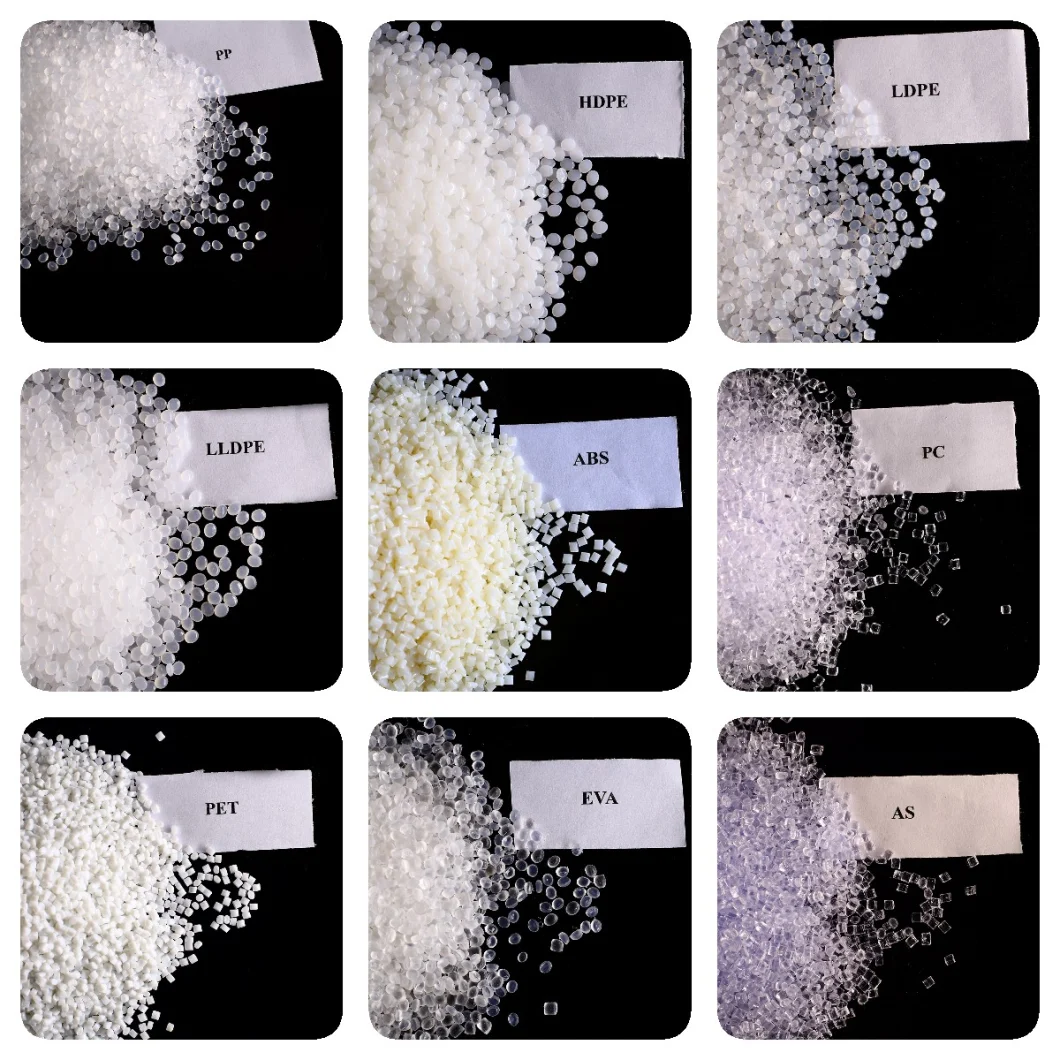

Our Main Products:

Send to us