ABS GF20 Fr V0 ABS Anti-UV Resistance Plastic and Resin Modified Plastics Cheap Plastic Pellets PC ABS

Basic Info

| Model NO. | ABS-66 |

| CAS No. | 9003-56-9 |

| Formula | ([email protected]@C3h3n)X |

| EINECS | 618-371-8 |

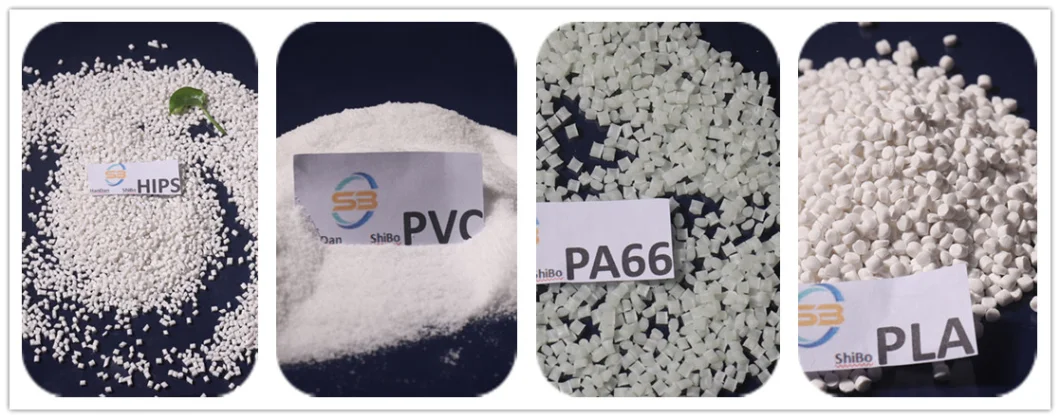

| Material | Acrylonitrile-Butadiene-Styrene Copolymers/ABS |

| Usage | General Plastics, Engineering Plastics, Specialty Plastics |

| Plastic Properties After Heated | Thermoplastic Plastics |

| Plastic Forming Method | Injection |

| Color | White/Black |

| Sample | Free |

| Delivery Time | 7-15days |

| Quantity | 25kg/Bag |

| Type | Virgin |

| Transport Package | Water-Proof Paper Plastic Bag |

| Specification | 25Kg/bag |

| Trademark | SHIBO |

| Origin | China |

| HS Code | 3903309000 |

| Production Capacity | 20000tons/Year |

Product Description

ABS is a terpolymer of three monomers: acrylonitrilA), butadiene (B) and styrene (S). The relative content of the three monomers can be changed at will to make various resins. ABS plastic has the common properties of three components. A makes it resistant to chemical corrosion, heat resistance, and has a certain surface hardness, B makes it have high elasticity and toughness, and S makes it have the processing and molding characteristic of thermoplastics and improve electrical properties. performance. Therefore, ABS plastic is a kind of "tough, hard and rigid" material with easy-to-obtain raw materials, good comprehensive performance, low price and wide range of uses.

Properties:1.Stable shrinkage, good dimensional stability, low warpage

2.Good processability

3.Balance mechanical properties

4.Good exterior, no need to be plated, sprayed

5.Flame resistant ABS resin largest application areas are the automotive, electronics and building materials.The automobile industry: Automotive instrument panels, exterior body panels, interior panels, steering wheel, panels, door locks, bumpers, ventilation tubes etc.Electrical aspects: Widely used in refrigerators, televisions, washing machines, air conditioners, computers, copiers and other electronic appliances. Product Parameters

| Properties | Test Method | Test Condition | Units | Typical Values |

| Physical | ||||

| Melt Flow Rate | ASTM D-1238 | 220ºC, 10Kg | g/10min | - |

| Specific Gravity | ASTM D-792 | 23ºC | g/cm3 | 1.03 |

| Ash | - | 800ºC,30min | % | - |

| Mechanical | ||||

| Tensile Strength | ASTM D-638 | 50mm/min | MPa | 46 |

| Elongation at Break | ASTM D-638 | 50mm/min | % | 14 |

| Flexural Strength | ASTM D-790 | 2mm/min | MPa | 62 |

| Flexural Modulus | ASTM D-790 | 2mm/min | MPa | 1800 |

| Impact Strength, IZOD non-notched | ASTM D-256 | 23ºC | KJ/m2 | - |

| -30ºC | KJ/m2 | - | ||

| Impact Strength, IZOD notched | ASTM D-256 | 23ºC | KJ/m2 | 17 |

| -30ºC | KJ/m2 | - | ||

| Thermal | ||||

| Heat Deflection Temp. | ASTM D-648 | 1.8Mpa | ºC | 93 |

| 0.45Mpa | ºC | 98 | ||

| Others | ||||

| Mold Shrinkage | ASTM D-955 | 23ºC | % | 0.6-0.9 |

| Flammability | UL94 | 1/16" | HB | |

1.Packing:Paper plastic composite bag, N.W 25 kg/bag.

20mt/20'FCL

2.Storage:

The resin should be stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not be piled up in the open air.

3.Transportation:

During transportation, the product should not be exposed to strong sunlight or rain and should not be transported together with sand, soil, scrap metal, coal or glass. Transportation together with toxic, corrosive and flammable substance is strictly prohibited

1.We are able to provide customized service based on your requirements.

2.Competitive prices - directly from factory to customer.

3.Advanced equipments for testing and manufacturing.

4.Professional and good after-sale service.

5.Free sample for testing.